Products

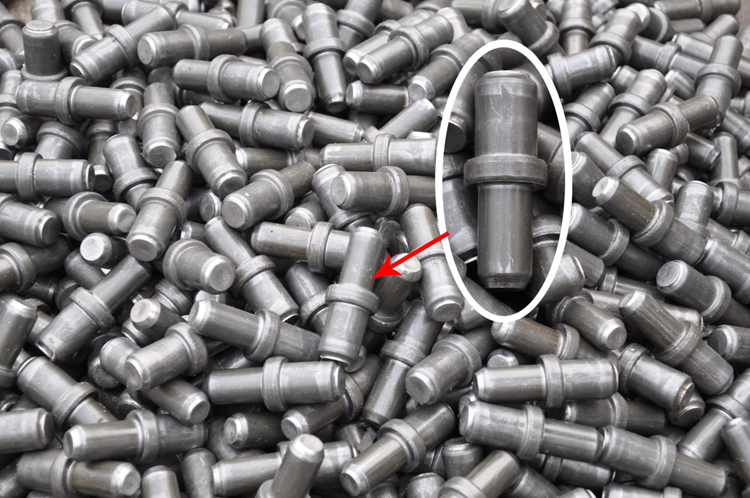

Retention Knobs

Knob BT-MAS Style. Metric

Knob DIN 69872 Style. Metric

Knob JIS B6339 Style. Metric

Knob ISO 7388/2 Type A . Metric

Knob ISO 7388/2 Type B . Metric

Knob MAZAK & MITSUI Style. Metric

Knob ANSI Style. Metric & Inch

Knob CAT-BT Style. Metric & Inch

Knob Fits Morse Taper Holder

OTT Retention Knob

Knob Fits Wood Engraving Machine

Knob Fits Boring Machine

POM501H Knob Fits Mori Seiki NH8000

MAZAK-BT30 Metric

Zero Point Positioning Pull Stud